KOKOBOARD Innovation

Kokoboard is a social enterprise with the aim to operate business creatively while creating secondary income for poor farmers by buying agricultural waste products such as rice straws, coconut shreds, vetiver grass, and others (approximately 250,000 – 400,000 baht/year). By doing this, the operation also reduces the amount of carbon dioxide released into the atmosphere through burning processes (100-180 ton per year), thereby mitigating the global warming from the agricultural sector efficiently. Instead, the agricultural wastes are turned into materials to replace wood such as rice straw board and cocodust board.

Kokoboard is a social enterprise with the aim to operate business creatively while creating secondary income for poor farmers by buying agricultural waste products such as rice straws, coconut shreds, vetiver grass, and others (approximately 250,000 – 400,000 baht/year). By doing this, the operation also reduces the amount of carbon dioxide released into the atmosphere through burning processes (100-180 ton per year), thereby mitigating the global warming from the agricultural sector efficiently. Instead, the agricultural wastes are turned into materials to replace wood such as rice straw board and cocodust board.

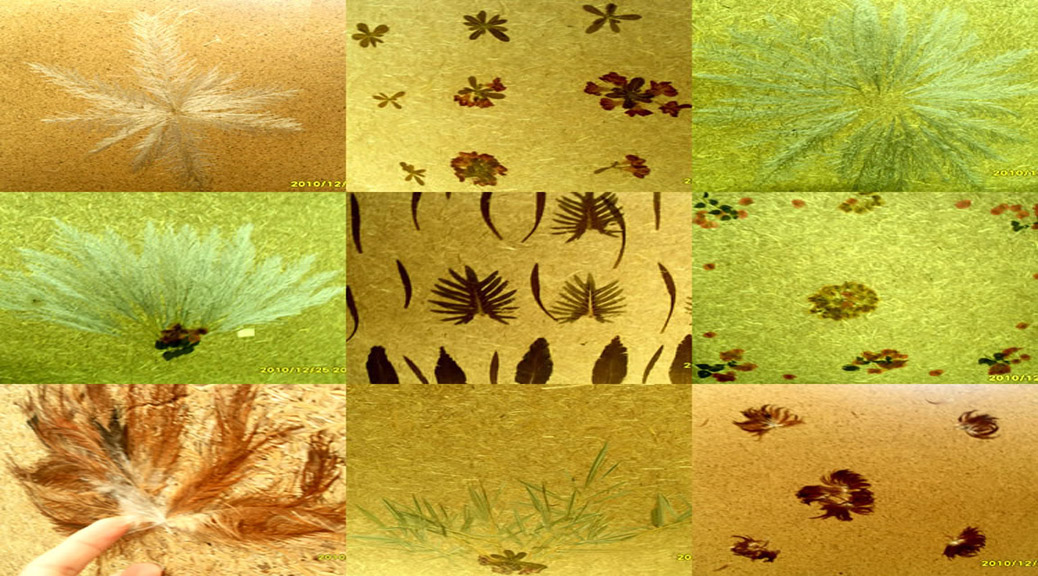

The size of these boards are 122 x 122 cm with 7 thicknesses (4, 6, 8, 10, 12, 15, and 20 mm). They can be used for interior design such as for decorating walls and ceiling, as well as for making various furnitures giving a unique design and color from nature. More importantly, these boards are free of formaldehyde (a cancer causing agen based on research), flame retardant, and moisture resistant. It is creative value-added products that alleviates deforestation problems (about 92.7 trees or 11.5 rai per year are saved). Users of these boards contribute truly to poverty alleviation and conservation of natural resources.

The size of these boards are 122 x 122 cm with 7 thicknesses (4, 6, 8, 10, 12, 15, and 20 mm). They can be used for interior design such as for decorating walls and ceiling, as well as for making various furnitures giving a unique design and color from nature. More importantly, these boards are free of formaldehyde (a cancer causing agen based on research), flame retardant, and moisture resistant. It is creative value-added products that alleviates deforestation problems (about 92.7 trees or 11.5 rai per year are saved). Users of these boards contribute truly to poverty alleviation and conservation of natural resources.

Kokoboard rises to this point by recognizing the importance of continuous research and development of new technologies, which was initiated by the participation in the ITAP project or Designing Kokoboard Production System (September 1, 2007). After the production line has been established successfully, another ITAP cooperation project for another research development for flame retardant and using ‘glue’ as a factor to increase capacity of the factory. As a result, a quality product was produced, which is the rice straw and cocodust boards that is highly moisture resistant and flame retardant.

Kokoboard continues to research and develop new technologies. Currently, success has already been proven with the production of peanut shell board and sun flower board including developments of designs pressed on the board from other natural materials. It also supports students from various institutes in research and provides services to develop boards from other industrial wastes such as curtain cloth board, jeans cloth board, jute board, and coffee wastes with sugar cane wastes board.

Currently, Kokoboad’s research and development projects for new innovative technologies are supported by both governmental and private funds from within Thailand and abroad. All projects are related to conservation of natural resources and to increase more income for farmers. Important projects that are being implemented from 2011 are as follows:

1. Creative Heater for Strawboard Production Line project is supported by the E-idea project by the British Council and LRQA to open opportunities, give supports, and challenge competitors to transform ideas and dreams into reality.

At the basic level, Kokoboard Co, Ltd. has succesfully produced rice straw, sun flowers, rice husk, and coconut dust. However, in the production process that is dependent on electricity and heat, carbon dioxide is still being produced indirectly because most electricity production in Thailand comes from burning coals or from dam constructions. With this reasoon, Kokoboard planned to develope alternative energy source such as from the Gasifier or producing heat from biomass by using wastes products and agricultural wastes to be the fuel for heat production. This heat is used during the high pressure to compress rice straw board of 60 x 60 cm. The main goal for this project is to develope innovative techlogy for cleaner production, which will make our products will be truly environment friendly and safety for health. For more information, please visit http://th.e-idea.org/eidealist/step-ups1

2. Project to expand and develop products or production process called “Research On Production Process in Rustic Furniture from Eucalyptus C amaldulensis Logs” was granted funds from the National Innovation Agency’s Project called “Coupon Innovation”

While the population growth continues to rise and the increase in basic living standards for people continues, the production from forests had decreased. This demand puts a pressure on the forest. Even though forests can be reforested and afforested, it will take a long time for trees to grow. Consequently, more attention has been given to growing fast growth trees such as Eucalyptus camaldulensis to replace forests that had been destroyed to conserve the balance in nature. The important point is for households to have sustainable consumption of woods as well as for production at the industrial level, which will increase in the future. In order to reduce deforestation from tree felling directly from the forest, many are now growing the Eucalyptus camaldulensis at the industrial scale for chipped wood making to supply Particle board industry, and fiber for MDF Board industry, and paper. But, these wood cannot be used for other quality wood work. Even for the production of fibre and paper, the demand for the appropriate size of trees in the production process is problematic for farmers because if the the tree is not a suitable size, it is not accepted by the factory. Therefore, woods that are too large are left in large amount in the fields or along the periphery that has not been used for benefits, while wood is carce and there is a lot of need in the market.

The main goal of the project is to have rustic furniture model that will be profitable in the market from forestry plantation. This will also include tools and materials specific for the production process of rustic furniture with the framework of mortise and tenon and tongue and groove. This is for easy disassembling of each part in the rustic furniture model that is approrpaite.

3. Expansion project and development of products or production process called “Biomass for Strawboard Production”

Objectives:

– To reduce costs of production process by using heat energy from biomass in replacement of electricity from the grid system.

– To design and develop production process replacement materials by using heat from biogas

– To reduce the time factor to be used in the production process for efficiency

– To reduce the amount of carbon dioxide into the atmosphere 4. Emergency Green Toilet Design and Production project is in the process of evaluation from Unltd Thailad (Unlimited Thailand), which is managed by Change Fusion.

This project helps to solve natural disasters in the short-term to ease the suffering of people who were affected by floods. Government and private entities have always provided basic necessities during the flood, draining water rapidly, creation of flood protection walls to mitigate property damanges from the flood, but there is one important factor for living and it is a problem that has not been given due attention, this is human excretion and human wastes during the flood. It is very important that health issues, mental and emotional health, and sanitary issues of those affected and for society at large must be addressed. It is also a part of preventative measures against water-borne diseases that comes with human wastes in the water or undrained water.

Emergecy Green Toilet model is highly moister resistant, which is appropriate and practical to the situation. It will also help people refrain from touching the water and moisture as well as this toilet has a long life. Since some areas are flooded and the water is stagnant for a long time in combination wtih heavy rainfall, the toilet has its weakness.

The emergency green toilet model will use agricultural wastes, wood particles from wood industrial wastes from the production process, and wood from forestry plantation. These raw materials will be used to produce a toilet with suitable size, strong, and brings good feelings to users in terms of strengths.

The emergency green toilet model can be assembled and disassembled rapidly and easy as well as convenient for transportation. The assembling and disassembling process is easy and conveneint after use including storage and land filling, which these materials can degrades naturally or it can be used for other purposes.

[/vc_column_text][/vc_column][/vc_row]